Last Updated on September 7, 2023 by Ecologica Life

It is a testament to human intelligence to be able to observe an ancient structure that is thousands of years old. Take the Egyptian pyramids, for example – people still argue about how they were built. It is often said that even with today’s technology we would struggle to replicate such feats.

How much knowledge and wisdom has been lost over the years? We may never know. However, we may have recently discovered how some Roman structures have lasted 2000 years. What is more, we may be able to use these secrets for our own buildings!

The enduring legacy of ancient Roman architects continues to fascinate scientists and engineers alike.

Discovering what makes ancient Roman concrete buildings so durable has opened up new opportunities. With this new knowledge we can reduce carbon dioxide emissions and revolutionise modern buildings.

This article explores the fascinating properties of self-healing concrete. We will also explore how ancient wisdom can be used as a sustainable solution for the future.

Table of Contents

The Secret Ingredients the Romans Put into Their Concrete

Roman concrete has stood the test of time for more than two millennia. In stark contrast, modern concrete, despite our superior technology, doesn’t last nearly as long. Modern concrete also doesn’t survive as well in salty water, unlike its Roman counterpart.

Roman concrete wasn’t a hapharzard mixture of ingredients; rather, the Romans put a lot of research and experimentation into its composition.

The secret of its strength lies in the use of a special recipe. Today’s concrete relies heavily on Portland cement. The Romans used a mixture of lime, volcanic ash (pozzolan) and water.

Pozzolan was a key ingredient that enhanced the concrete’s strength and durability. Pozzolan is a reactive volcanic ash that comes from the Pozzuoli area of the bay of Naples, near Mount Vesuvius.

Pozzolan has been in the Eastern Mediterranean since 500-400BC. It was first pioneered by the ancient Greeks, but it was the Romans who developed it into its full potential.

The Mystery of Lime Clasts

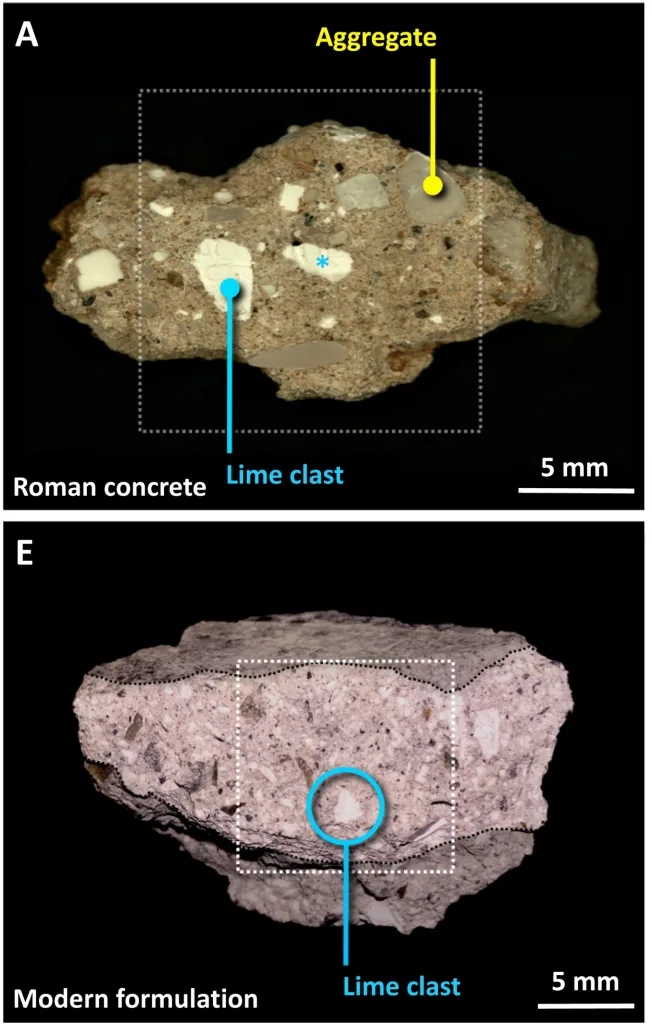

Recent studies of Roman concrete samples have shed light on a key characteristic: the presence of lime clasts.

Lime clasts are suspended chunks of lime that result from a technique known as ‘hot mixing’. Unlike the traditional method of hydrating quicklime, hot mixing involves adding quicklime directly into the concrete mix without hydrating it first.

Throughout the Roman Empire, these lime clasts have been found within concrete. It is likely that these lime clasts are not accidental. The deliberate inclusion of large lime clasts in the concrete matrix is thought to be the key. And is the real reason why Roman concrete is exceptionally durable.

The durability and strength of Roman concrete is thought to be due to a unique chemical reaction between seawater, pozzolan and quicklime.

This created a rare crystal called tobermorite. As seawater seeped into tiny cracks, it reacted with phillipsite, which occurs naturally in volcanic rock, to form aluminous tobermorite crystals.

This compound is considered by some to be potentially “the most durable building material in human history”. In stark contrast, modern concrete structures exposed to seawater often show signs of deterioration within just a few decades.

Self-Healing Concrete

Building on the knowledge gained from Roman concrete, scientists have made significant advances in the development self-healing concrete.

This cutting-edge technology enables concrete to repair itself, extending its lifes and reducing maintenance requirements.

When cracks form in self-healing concrete, water penetrates through the lime clasts. In the presence of water, these lime clasts trigger a recrystallisation process that effectively seals the cracks.

Laboratory tests have shown that concrete produced using the “hot mixing method” can exhibit remarkable self-healing properties. Cracks in the concrete can close in as little as two weeks.

Environmental Implications and Sustainable Construction

The environmental impact of concrete production cannot be ignored. Ordinary Portland cement is a critical component of modern concrete, but its production has a serious environmental impact. For every metric tonne of Portland cement produced, up to one metric tonne of CO2 is emitted.

In 2021, concrete production accounted for approximately 7 percent of global carbon emissions. As the demand for concrete continues to rise, reducing its environmental impact becomes increasingly important.

One way to reduce this environmental impact is to use self-healing concrete, as the Romans did. Longer lasting concrete structures with fewer repairs can improve their economic lifespan and help the environment. We can create structures that stand the test of time better.

Applying Ancient Wisdom to Modern Construction

The rediscovery of the secrets of Roman concrete offers a remarkable opportunity for sustainable construction. Incorporating pozzolan and lime clasts into modern concrete production could pave the way for more durable, environmentally friendly structures. However, further research and development is needed to optimise these techniques for modern applications.

Scientists, engineers, and construction professionals are collaborating to refine the composition and production of Roman-inspired concrete. The aim is to produce a concrete that is as strong and durable as Roman concrete, or possibly even better.

If we can make buildings that last longer, then their value will be greatly enhanced. The owners of these long-lasting buildings will save money in the long run.

In addition, exploring the use of locally sourced and environmentally friendly materials in concrete production can further enhance sustainability.

Researchers are actively investigating alternative options that can minimise CO2 emissions and reduce reliance on non-renewable resources. These include things like recycled aggregates to bio-based binders.

Conclusion

The enduring legacy of Roman buildings continues to inspire scientists and engineers in their search for sustainable construction solutions.

By understanding the composition and techniques used by the Romans, we can harness the durability and environmental benefits of ancient concrete for the modern world.

The deliberate inclusion of lime clasts and the development of self-healing concrete offer promising ways to reduce CO2 emissions. In addition, we can use this ancient wisdom to extend the life of structures, and promote green building practices.

By taking inspiration from the past, we have the opportunity to create a more sustainable future. A future in which concrete structures stand the test of time while preserving the environment.

Veni, Vidi, Vici (We came, we saw, we conquered)

Julius Caesar, Roman emperor.